Wakame seaweed farmers produces seedlings for themselves utilizing advanced technology.

In the Maruyama district of the Minami Awaji Fisheries Cooperative in Hyogo Prefecture, a leading production area of farmed wakame seaweed (Undaria pinnatifida) in Japan, the wakame seaweed farmers are tackling artificial culture of seedlings, facing their shortage due to global warming. Advanced technology developed in a laboratory was put into practice. Behind that were enthusiasm of the farmers and researchers and support by the community. Their challenge started for stable supply of seedlings is leading to creation of a new brand of wakame seaweed.

Shortage of seedlings due to climate change threatened the survival of wakame seaweed farming.

In the Maruyama district of the Minami Awaji Fisheries Cooperative (hereinafter referred to as Minami Awaji Co-op), large-scale wakame seaweed farming with a total 450 km of farming ropes is run. Although the exact yield is not available as wakame seaweed farming in Hyogo Prefecture is going fisheries sixth sector industrialization, wakame seaweed of Maruyama accounts for more than 80% of all the prefectural production. Maruyama boasts the largest production capacity in western Japan as a single organization.

The farmers used to buy seedlings from seedling suppliers. Since around 2010, they have been facing a serious shortage of seedlings. It is getting more and more difficult to get them every year. One of the main causes is that constant production of seedlings in outdoor tanks or in the sea is difficult because the water temperature from summer to early autumn is higher than before due to climate change.

Average summer temperature in Tokushima (June to August): 25.7°C (average from 1981 to 2010)

* The bar graph shows deviation from the reference value of each year (30-year average from 1981 to 2010). A blue bar represents a five-year moving average of deviation and a red line represents a long-term trend. (Source: Tokushima Local Meteorological Office)

In the Maruyama district, something unusual have been happening for the past 15 to 20 years. As a decline in water temperature in early autumn is delayed, flathead mullet, girella, Japanese amberjack, red sea bream and their fingerlings linger in this sea area and eat wakame seaweed when the farming has just begun. To avoid that, planting (rearing in the sea) has to be delayed until the very last minute.

Seedlings are sold first to farmers who begin planting (rearing in the sea) first. As the time of planting is delayed, the Minami Awaji Co-op is last to come and has a small quantity left. Representative auditor of the Minami Awaji Co-op, Kazuaki Kamei, says that there has been no year without worrying about seedlings in autumn in the past several years.

“The seedling supplier warns us that there are no seedlings for Maruyama. We pay in advance to keep seedlings for us. However, even if we pay at a price of 3,000 yen, for instance, and ask the supplier to keep seedlings, another farmer buys them at 4,000 yen the next day. It is now a competition or an auction. We have decided that all the farmers of Maruyama should place a bulk order together to be at an advantage but that didn’t work. We understand seedling suppliers won’t be able to say No to their long-time customers if they are desperate. If their fellow suppliers fail to produce seedlings, they give some to help them. The price of seedlings has jumped to 1.5 times higher than that five years ago.”

Last year, we could not get seedlings in the Naruto area and we had to go as far as Nagasaki Prefecture to buy them. The seedlings didn’t agree with the seawater of the area and all the seedlings inserted into the ropes dropped from the ropes and they were gone.

Free-living gametophyte technology is put into practice to achieve constant supply of wakame seaweed seedlings

To overcome the difficulty the farmers were suffering, Kyosuke Niwa at the Fisheries Technology Institute of the Hyogo Prefectural Technology Center for Agriculture, Forestry and Fisheries suggested Kamei “Why don’t you produce seedlings yourself using the technology of free-living gametophyte?”

In spring, mekabu, flowering sprout, is produced at the root of wakame seaweed and it releases a large number of small zoospores. Zoospores grow into threadlike gametophytes and divided into males and females. In autumn, male and female gametophytes are fertilized and developed into seedlings.

The free-living gametophyte technology, in which male and female gametophytes are separately stored and cultured, enables the control of the fertilization timing and therefore makes it possible to time seedling production to fit the right time for farming. There are more advantages. For example, uniform seedlings can be produced every year and an improved variety may be produced by hybridization.

This technology remained at laboratory level and it was not put into practice for reasons. The operation of a microscope to separate male gametophytes from female gametophytes was difficult for farmers. Special equipment including incubator was needed. In addition, gametophytes fertilized this way do not adhere to the strings properly. It was considered difficult for farmers to go through all the process and mass-produce seedlings.

Niwa devised a simplified method farmers could follow using readily available tools and started training in 2015.

“We had the farmers come to the Fisheries Technology Institute three or four times and practice a series of operations using a microscope. They seemed to be confused with many technical terms. At first they said “I cannot do this!” The more lessons they took, the more things they were able to do. Now, they have got much more familiar with the technique and they even devise their ways.”

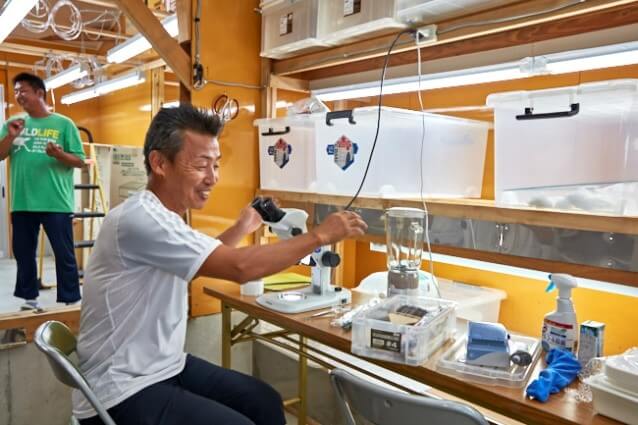

In 2016, Minami Awaji Co-op purchased microscopes and incubators using a subsidy granted by the District Administration Office. The farmers converted a fishing gear warehouse for themselves and started seedling production there. They succeeded in producing 30% of necessary seedlings in the first year.

The farmers’ enthusiasm and ideas produced an original variety.

Delicate work is required all through seedling production from collecting zoospores in spring to separating male and female gametophytes. Separated gametophytes are placed into test tubes one by one and cultured in incubators during summer.

Mainly 16 farmers in their 20s to 50s are in charge of the seedling production. Except for the wakame seaweed farming season, they do different fisheries, such as those using boat seines, trawls, octopus traps, fishing rods and sea bream fishing net. As they have breaks and days off at different time, they do their job of seedling production separately in their spare time.

“Last year, we produced about 500 test tubes of gametophytes. This year, we are going to increase them to 2000 as we need more. A quota for each of us is 150 test tubes. Sometimes, I cannot tell if a gametophyte is male or female as it looks like an in-between. In that case, I ask a colleague next to me, “It looks like a male but what do you think?” If that person cannot tell, I ask one next to him. Basically, we work in a group of two or three. We have two microscopes. About five people use one microscope together. Younger people are quick to learn and so they are usually doing the job alone in their spare time.”

In early autumn, cultured male and female gametophytes are mixed in a blender and attached to strings and an environment for fertilization and germination is created. Niwa visits the worksite to give advice at critical moments of important operations. He said he was amazed at their steady progress.

“They have made everything from special lighting shelves, height-adjustable fluorescent lamps and electrical wiring, let alone the building itself, by hand. I was amazed at their clever ideas for so many things. Based on their last year’s experience, they have been making improvements to the equipment one after another. Mr. Kamei heading the team and Mr. Nishida, Seedling Department Manager are very keen. Co-op president Mr. Koiso thinks it important that all of them make efforts together. That boosts the team’s morale and leads to such a great achievement. I will continue to help them produce more and more fertilizable gametophytes while expanding the scale of production.”

In 2017, the team newly received financial support from the city, cooperative financial institutes and banks and bought more incubators and improved the seedling equipment. The community’s expectations are growing, too.

“Three years ago Mr. Niwa told me, ‘If successful, you will be able to combine male and female gametophytes to make wakame seaweed you like. Would you like to try?’ Last year, we and Mr. Niwa tried various combinations and came up with the species we are now growing. It has got all the features good wakame should have. It is nice and black and fleshy. It grows quickly and increases in weight. We gave the seedlings of this species to a seedling supplier we have business with and asked him to farm them. He was surprised and said, ‘Such wakame seaweed can grow in the sea of Naruto? I have never seen wakame seaweed like this!’ We named the species ‘Niwa seedling.’”

The day may come soon when the Maruyama brand produced by fishermen leads wakame seaweed farming in the Naruto area.

(Posted on March 6, 2018)